| Listen to our audio presentation: A Journey Through the History of Quantum Mechanics |

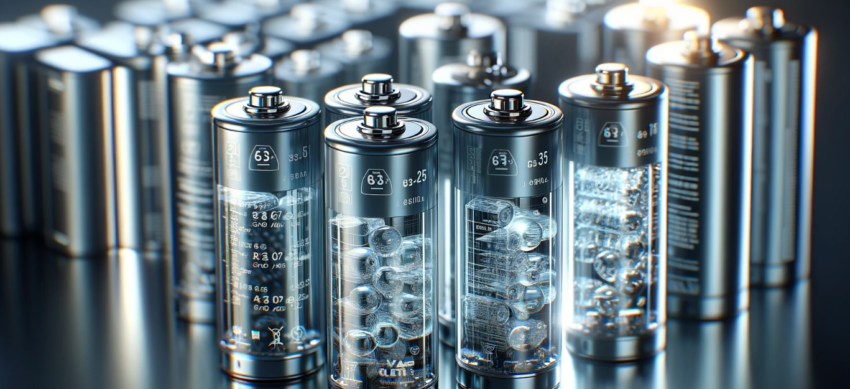

The quest to solve one of the most pervasive safety and durability problems of rechargeable batteries has yielded an exciting advancement – high-performance fibre batteries with polymer gel electrolytes. This development bears promising implications for a variety of sectors, particularly wearable electronics and electric vehicles, with potential uses even in extreme conditions such as firefighting and space exploration.

Polymer gel electrolytes (GPEs) offer substantial advantages over traditional liquid electrolytes. While the latter raises safety concerns such as leakage, combustion, and flammability, GPEs eliminate these issues, standing as a formidable and transformative technology for energy storage systems.

Replacing liquid electrolytes with GPEs could enhance the safety and flexibility of wearable batteries. However, the ongoing challenge has been to overcome the inferior electrochemical properties resulting from a poor interface between the GPE and battery electrode. To address this, researchers have developed an approach that introduces channel structures within the electrodes. When a monomer solution is infiltrated into these channels and polymerized, an intimate and tenacious interface is formed with the electrode, enabling new high-performance wearable batteries.

Researchers have also woven fibre lithium-ion batteries (FLBs) into a large textile. This 50cm x 30cm textile can provide an output of up to 2,975 mAh, remaining operational even in extreme conditions such as temperatures between -40°C and 80°C, making it suitable for a multitude of applications.

When it comes to electric vehicles, GPEs offer much in terms of high-energy-density and safe rechargeable solid-state batteries. They deliver high ionic conductivity and mechanical stability, which are optimal for quasi-solid-state batteries used in electric vehicles.

GPEs are the product of a unique synthesis of properties found in solids and liquids. They consist of a solid polymer matrix which encapsulates or stores the liquid electrolytes, enhancing the ionic conductivity at ambient temperatures while also offering operational safety, mechanical flexibility, and non-combustibility.

The ongoing research and advancement of GPEs and the vast array of their potential applications underline their crucial role in shaping the future of energy storage and battery systems. Whether harnessed for wearable tech, electric vehicles, or renewable energy, GPEs are undeniably driving a revolution in pioneer battery technology.

Information Box:

– GPEs are safer alternatives to traditional liquid electrolytes.

– GPEs could solve energy density and safety issues in electric vehicles.

– Practical applications of GPEs include wearable batteries and textiles.

– GPEs have a unique combination of properties found in solids and liquids.

References:

1: Nature.com, “High-performance fibre battery with polymer gel electrolyte.”

2: MDPI.com, “Performance Applications | GPE”

3: Digital News Report, “Fibre batteries with polymer gel electrolytes represents a significant advancement.”